When it comes to surface preparation, selecting the right equipment can make the difference between a successful project and costly delays. VonArx is worldwide known in the area of surface preparation with machines and tools that are user friendly, strong and long living. Following the recent acquisition of German-based shotblaster manufacturer IMPACTS GmbH, VonArx now offers an even more comprehensive range of surface preparation solutions.

This guide will help you understand the key differences between scarifiers, shotblasters, grinders, and concrete shavers, enabling you to choose the right tool for your specific application.

Understanding Your Surface Preparation Options

Scarifiers: The Aggressive Workhorses

Scarifiers are ideal where paved surfaces need to be roughened, grooved, cleaned, or where layers need to be removed. These machines are designed to mechanically chip away surface material using rotating drums equipped with carbide-tipped cutters.

Key Characteristics:

- Working Method: Mechanical chipping action

- Surface Finish: Rough, textured profile

- Best Applications: Paint removal, concrete cleaning, surface roughening, marking removal

- Versatility: Various cutter types for different materials and applications

VonArx Scarifier Range:

The VA 10 L (100mm working width) is perfect for small areas and tight corners, featuring a swivel handgrip and 230V household supply compatibility.

The FR 200 (200mm working width) excels at pavement marking removal and precision work on small to medium surfaces. Available in both gasoline and battery-powered versions, with the battery version offering 23 minutes of running time per battery and 45-minute recharging.

For larger surfaces, the VA 25 S and VA 30 S (250mm and 300mm respectively) offer enhanced user comfort with vibration absorption systems and variable depth adjustment.

The VA 30 SH represents the heavy-duty option with hydraulic traction, making it ideal for cleaning large areas of concrete, removing concrete slurry, dirt, plastic or roughening smooth surfaces, and is also used for paint removal and rubber lining removal at airports.

VonArx also offers the VA 35 SH (350mm/14″ working width), a larger and more powerful scarifier for demanding surface preparation tasks, available in:

- 400V/50Hz: 11kW/15HP

- 480V/60Hz: 12.6kW/17HP

Shotblasters: Precision Surface Profiling

Through the acquisition of IMPACTS GmbH, VonArx now offers professional shotblasting equipment. The Shotblasters Machine Series by VonArx is powerful and compact blast machines designed for various surface preparation applications, whether you need to work on medium-sized horizontal surfaces, small to medium areas on concrete, screed, asphalt, or difficult-to-reach small areas.

Key Characteristics:

- Working Method: High-velocity steel shot projection

- Surface Finish: Uniform, controlled profile

- Best Applications: Concrete profiling, coating removal, surface texturing

- Advantage: Consistent surface profile, efficient material removal

VonArx Shotblaster Range:

The VonArx Shotblasters are powerful and compact blast machines available for various surface preparation applications on medium-sized horizontal surfaces, small to medium areas on concrete, screed, asphalt, or difficult-to-reach small areas. These machines represent VonArx’s expansion into professional shotblasting technology following the IMPACTS acquisition.

Grinders: Precision Surface Refinement

VonArx’s grinding machines are reliable and user-friendly equipment designed for versatile grinding applications, with adjustable grinding pressure and compatibility with diamond tools, offering precise control and exceptional results.

Key Characteristics:

- Working Method: Diamond disc grinding

- Surface Finish: Smooth, precise finish

- Best Applications: Surface leveling, polishing preparation, minor material removal

- Precision: High control over material removal depth

VonArx Grinder Range:

VonArx offers grinding machines designed for versatile grinding applications with adjustable grinding pressure and compatibility with diamond tools.

Featured Model – FG250S:

The FG250S represents VonArx’s latest innovation in grinding technology. This powerful, versatile surface grinder combines cutting-edge features including a water cooling system that keeps grinding disks at optimal temperatures and an integrated leveling tool for precise results.

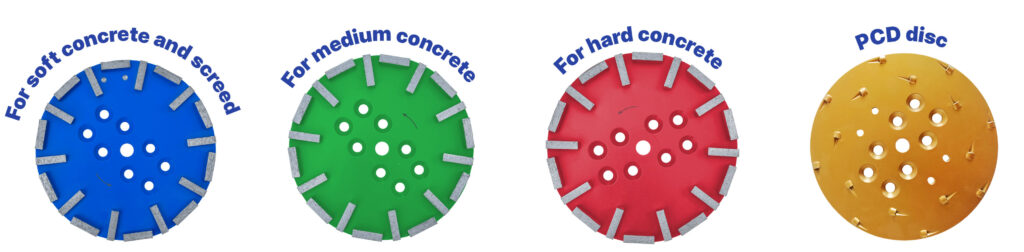

The system includes specialized diamond discs for different concrete types:

- 20 Segment Disk for Soft Concrete & Screed

- 20 Segment Disk for Medium Concrete

- 20 Segment Disk for Hard Concrete

- 16 Segment PCD Disc for specialized applications

FG250 Series: Available in 400V/50Hz and 480V/60Hz configurations with 5.5kW power output for professional applications.

FG500: VonArx’s larger grinder model, available in 400V/50Hz and 480V/60Hz configurations for heavy-duty grinding applications requiring higher power and wider coverage.

Concrete Shavers: The Precision Specialists

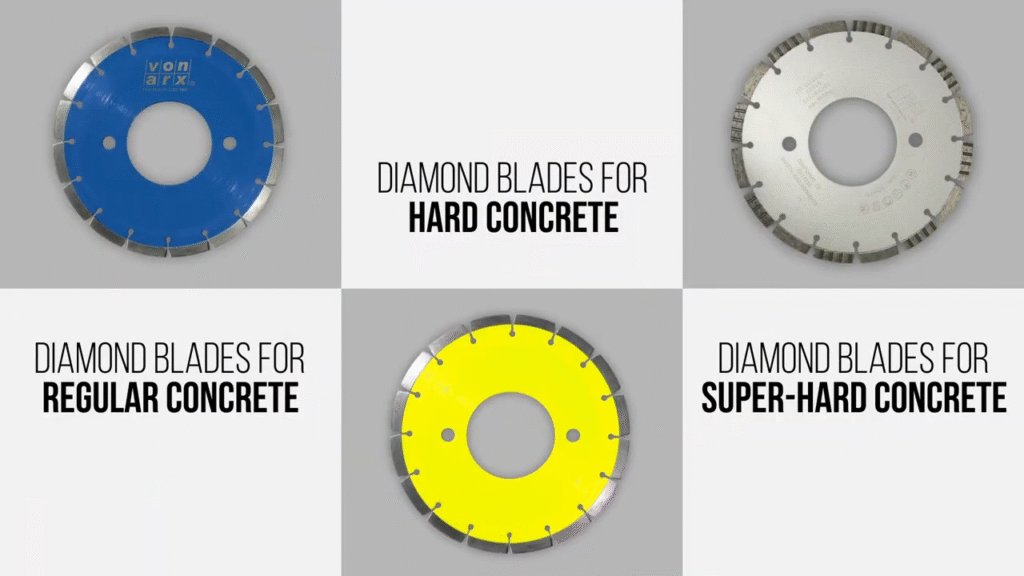

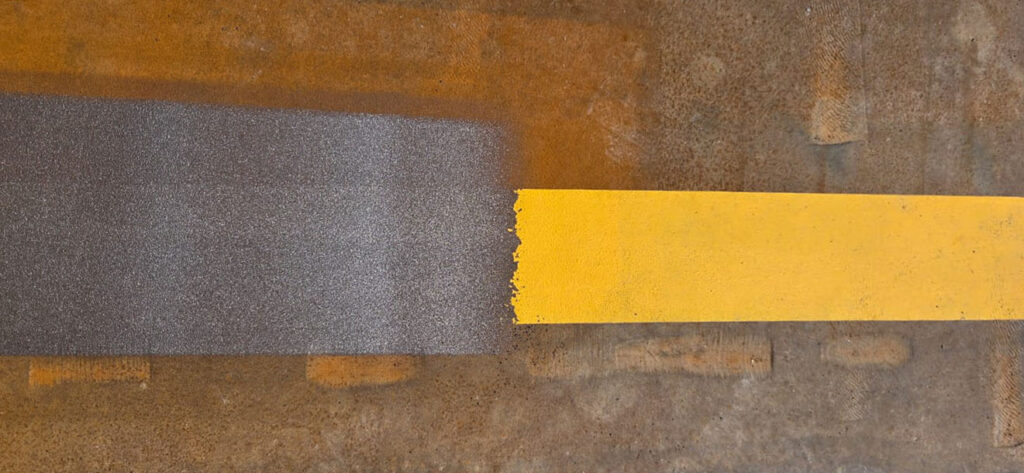

With VonArx shavers, the surface is carefully “grinded off” instead of chipping it away. These machines run calmly and produce a smooth surface, equipped with a drum containing diamond blades that remove material very precisely.

Key Characteristics:

- Working Method: High-speed diamond blade rotation

- Surface Finish: Extremely smooth and precise

- Best Applications: Floor leveling, concrete curb removal, joint grooving

- Precision: Highest accuracy in material removal

VonArx Shaver Range:

The DTF 25 SH (250mm working width) requires water cooling to prevent diamond blade overheating and is available as an 11kW electrical version with hydraulic traction.

The DTF 35 SH (350mm working width) offers versatility for multiple applications including:

- Levelling concrete floors and removing undulations

- Reducing concrete risers and removing concrete curls

- Profiling for new overlays and barn grooving

- Creating anti-slip surfaces and anti-seismic joints

- Surface cleaning for coating or polishing preparation

Choosing the Right Equipment

For Aggressive Material Removal and Surface Roughening

Choose Scarifiers when you need to:

- Remove thick coatings or paint

- Create rough surface profiles for bonding

- Clean heavily contaminated concrete

- Remove pavement markings

- Work in tight spaces (VA 10 L) or large areas (VA 30 SH)

For Consistent Surface Profiling

Choose Shotblasters when you need:

- Uniform surface texturing

- Precise concrete profiling before coating application

- Efficient removal of thin coatings

- Work on vertical surfaces (with balancer)

- Professional-grade surface preparation standards

For Surface Refinement and Polishing Preparation

Choose Grinders when you need:

- Smooth surface finishing

- Precise material removal control

- Surface leveling and smoothing

- Preparation for polished concrete systems

- Work with various diamond tooling options

For Ultra-Precise Material Removal

Choose Concrete Shavers when you need:

- Perfect floor leveling

- Smooth joint cutting

- Minimal surface disturbance

- Precise depth control

- Preparation for high-end flooring systems

Integration with Dust Management

Regardless of your equipment choice, proper dust management is crucial. VonArx offers robust and safe dust extractors designed to be connected to scarifiers, shavers, grinders, and saws, equipped with H13 HEPA filters, JetPuls filter cleaning, and Longopac collection systems.

Conclusion

The key to successful surface preparation lies in matching your equipment to your specific application requirements. VonArx’s comprehensive range, now enhanced by the IMPACTS acquisition, provides solutions for every surface preparation challenge. Whether you need the aggressive action of scarifiers, the precision of shotblasters, the refinement of grinders, or the ultra-precise control of concrete shavers, understanding each tool’s strengths will help you achieve professional results efficiently and cost-effectively.

For optimal results, consider factors such as:

- Required surface finish

- Material removal depth

- Project size and accessibility

- Subsequent coating or treatment requirements

- Environmental considerations and dust control needs

By selecting the appropriate equipment and maintaining it properly, you’ll ensure consistent, professional results that meet the highest industry standards.