Surface preparation equipment is crucial to many businesses because it makes efficient and effective surface preparation for coatings, repairs, and renovations possible. But one thing that is frequently disregarded is how much vibration these devices produce. In this post, we’ll look into the significance of vibration levels in surface preparation machines and examine how they may impact worker health as well as productivity. It’s essential to comprehend these aspects in order to maximize productivity and create safer work conditions.

Understanding Vibration Levels

When a surface preparation equipment is operating, vibration levels refer to the size and strength of the vibrations that are produced. The most common metrics for these vibrations are acceleration, amplitude, and frequency. Vibration levels are influenced by a number of variables, including machine design and surface characteristics. Vibration characteristics are influenced by the machines’ design and construction, including factors like weight distribution, motor balancing, and structural integrity. Vibrations can also be amplified or dampened depending on the state and nature of the surface being treated.

Impact on Productivity

High vibration levels might have a negative impact on productivity when performing surface preparation chores. First of all, they may jeopardize the consistency of previously prepared surfaces, resulting in uneven coatings and perhaps rework. Excessive vibrations can also compromise the precision and accuracy of the operator’s operation, leading to poor surface preparation quality. Furthermore, increased vibrations make the machine less stable, which slows down operation and increases the time needed to do tasks. Additionally, vibrations can hasten the deterioration of machine parts, necessitating more frequent maintenance and repairs.

Effects on the Operator’s Health

Vibration levels have an effect that goes beyond productivity and endangers the operators’ health. Hand-Arm Vibration Syndrome (HAVS), a disorder that affects the nerves, blood vessels, and muscles in the hands and arms, can result from prolonged exposure to high vibration levels. Numbness, tingling, and decreased grip strength are symptoms. Another issue for operators using devices that produce significant amounts of vibration is Whole-Body Vibration (WBV). Back pain, troubles with posture, and a higher risk of musculoskeletal disorders can all come from it. Countries have developed regulatory guidelines for occupational vibration exposure to address these health risks, putting the onus on employers to offer training, implement safety precautions, and provide personal protective equipment.

Vibration Level Mitigation

Vibration levels in surface preparation equipment must be reduced if productivity and worker safety are to be improved. The choice of equipment is crucial because low-vibration machines can greatly reduce their negative effects on health and productivity. Advanced technologies can also be used to reduce vibrations, such as vibration isolation mounts and shock-absorbing polymers. Regular maintenance is crucial because it enables the detection and correction of problems that are the cause of elevated vibration levels. Vibrations can be reduced during operation by properly calibrating and balancing machine parts like blades and counterweights. Additionally, reducing needless vibrations and relieving operator stress can be accomplished by giving operators with thorough instruction on the proper machine operation procedures as well as by taking ergonomic considerations, such as adjustable handles and grips.

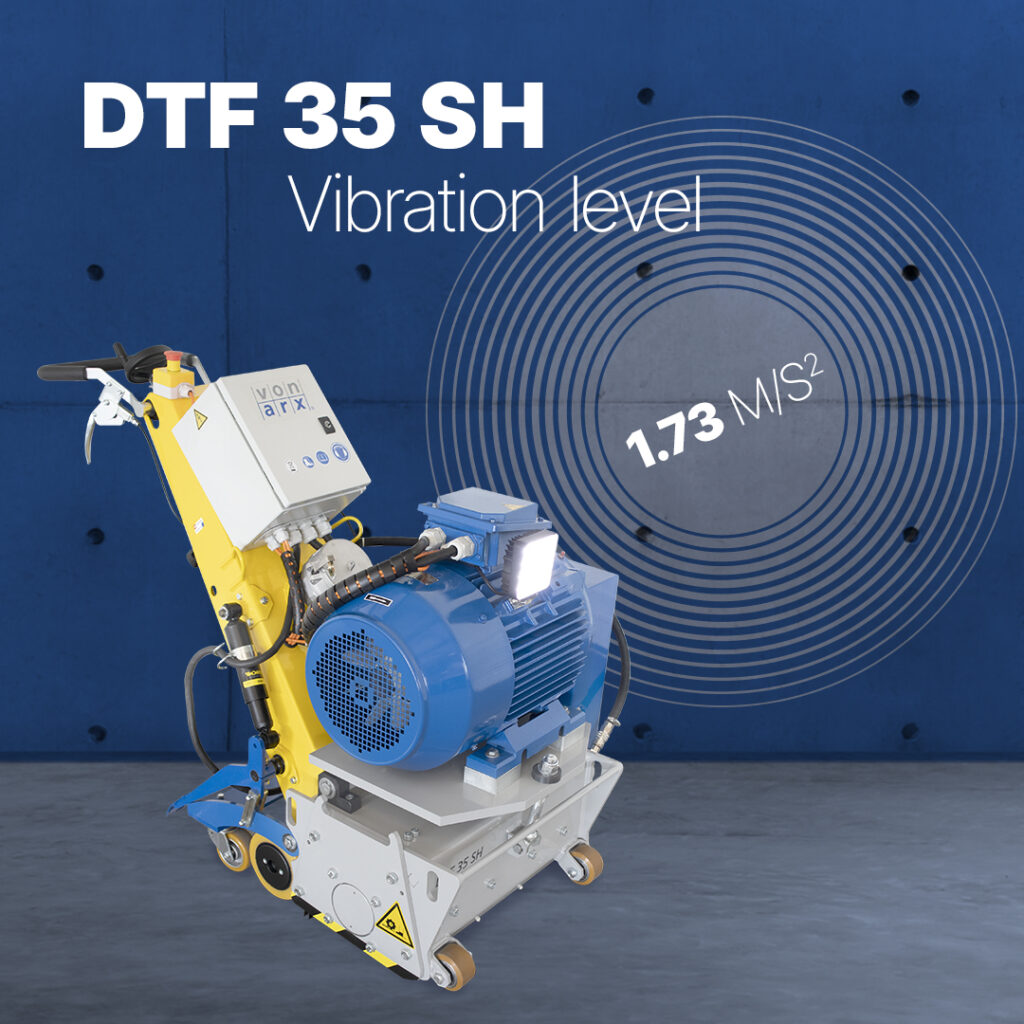

DTF 35 SH

The VON ARX concrete shaver “DTF 35 SH” is a renowned example of a surface preparation device that excels at maintaining low vibration levels. With a vibration level of just 1.72 m/s2, well below the recommended limits, the DTF 35 SH stands as a testament to the industry’s commitment to operator safety and productivity. Additionally, the DTF 35 SH’s low vibration levels improve surface preparation quality and provide accurate and consistent results. The DTF 35 SH shows how manufacturers may prioritize both operator well-being and operational excellence by integrating cutting-edge technologies and design components to minimize vibrations.

Conclusion

Given their major effects on productivity and worker health, vibration levels of surface preparation equipment shouldn’t be undervalued. Increased vibrations can result in deteriorated surface quality, decreased operating effectiveness, and potential long-term health risks. Prioritizing equipment selection, maintenance, and calibration procedures that reduce vibrations is crucial. Comprehensive operator training and ergonomic considerations can also improve safety and reduce risks associated with vibration. The well-being of workers may be guaranteed, and the results of surface preparation can be improved, by giving priority to the management of vibration levels in the workplace.

Learn more about how our low-vibration machine can make your work safer and more productive!